Описание Проекта

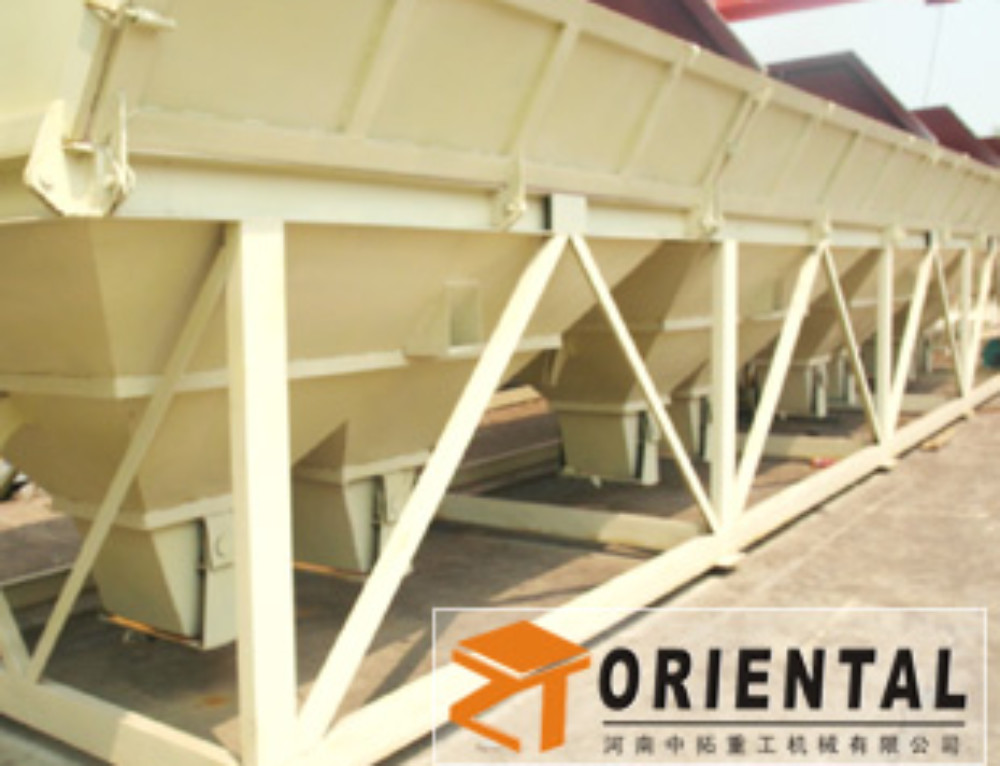

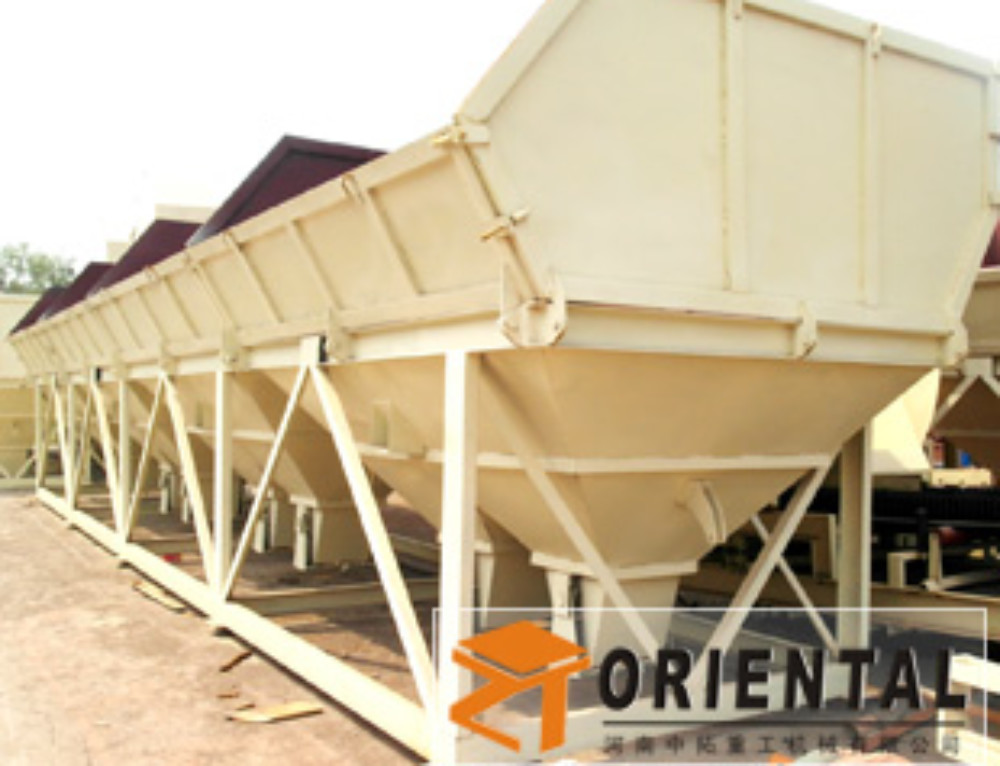

PLD 1600 Concrete Batching Machine

PLD series concrete batching machine is a kind of automatic batching equipment used on the foreground matched with the mixer. It can finish batching 3-6 kinds of material like sand,stone,цемент, и т. д.. automatically according to the concrete proportion designed by users.

![]()

| model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Weighing bucket

емкость |

800л | 1200л | 1600л | 2400л | 3200л | 4800л |

| Hopper capacity | 2*1.2m3 | 3*2.5m3 | 3*3m3 | 3*12m3 | 3*20m3 | 4*25m3 |

| Production rate | 48м3/ч

(dry material) |

56м3/ч

(dry material) |

75м3/ч

(dry material) |

120м3/ч

(dry material) |

160м3/ч | 280м3/ч |

| Batching accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Maximum weighing

value |

2000кг | 3000кг | 3000кг | 4000кг | 5000кг | 8000кг |

| Ingredients species | 2-3 | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 |

| Высота кормления | 2400мм | 2900мм | 2900мм | 4250мм | 4500мм | 2300мм |

| Feeder belt speed | 1m/s | 1m/s | 1m/s | 1.6m/s | 1.6m/s | 1.25m/s |

| власть | 3×3=9kw | 4×3=12kw | 3×4=12kw | 7.5кВт | 11кВт | 18.5кВт |

| Total weight | 2450кг | 4500кг | 5600кг | 8500кг | 10200кг | 14000кг |

| Размеры (L×W×H) |

1580*

2780* |

9400*

2020* |

9400*

2270* |

13200*

3250* |

13100*

3340* |

15520*

3900* |

PLD series concrete batching machine is a kind of equipment with automatically batching material on the front desk and using mixer together. It can automatically finishing the batching procedures of 2-5 kinds of materials (second grade concrete) such as sand, stone, cement according to users’ requirement. These serial products adopt electronic weighing, computer control, digital display, wired remote control operation, and have such advantages as accurate weighing, high precision batching, quick speed, strong control function and convenient operation. After this serial concrete batching machine with relative concrete mixer, different types and specification combined concrete mixing station can be formed.

1.Automatically finish the proportioning and measuring of sand and stone.

2.The control system is made up of controller and strong electricity part.

3.The controller has visual features like high weighing accuracy, rapid reacting speed, stable and reliable performance, strong anti-jamming ability, simple operation, и т. д..

4.It can control the specified proportioning times,and accumulate the total times automatically.

5.Customers can choose the numbers of proportioning bins according to different use.

Temperature sensor:

Supply the exact temperature of aggregate,applicable to some area such as high temperature,freezing and area with special requirement for temperature

Microwave hygronom:

Supply the exact water ratio of aggregate,during batching ,the corresponding water ratio is reduced and the batching precision is improved

Preheat pipe:

The outlet of the pipe is ready in advance,heating the aggregate through preheating gas,applicable to freezing area

Rainproof shed:

Avoid to drench aggregate ,applicable to rainfall area ,filtration shaker,supply you with eligible aggregate materials to improve the quality materials

We can design and make the batching system of aggregate according to the user’s circumstance,field and special requirement