Projektbeschreibung

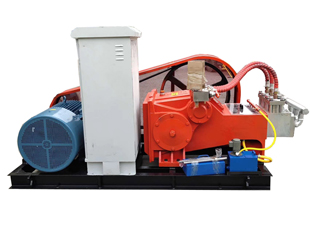

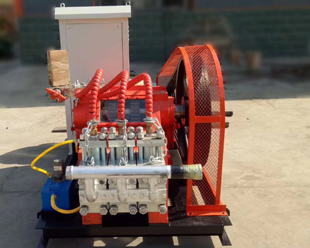

Hochdruckpumpen

In den folgenden Bereichen können Hochdruckpumpen verwendet werden:

○ Behandlung mit weicher Grundlage, Hochdruck -Rotationsstrahlverschmutzung;

○ Hochdruckwasserstrahl hilft bei der Breaking von Gestein und fallender Kohle;

○ Kohlemine unterirdische Hydraulikprops liefern Flüssigkeit;

○ Verankerungshydraulik -Expansion Metall -Pflasterstange, um Hochdruckwasser zu pumpen;

○ Unterirdische große Pipeline -Baggerreinigung;

○ Chemische Pumpe;

○ Hochdruckwasserstrahl, Horizontal durch Löcher bohren;

![]()

| NEIN | Haupttechnische Parameter | Einheit | |||

| Motorleistung | 55KW | 90KW | |||

| 1 | Motormodell | Ye2vp280m-6 | Ye2vp280m-4 | / | |

| 2 | Handlungsform | Horizontaler Hubkolben -Eintyp mit einem Schauspielstich | Horizontaler Hubkolben -Eintyp mit einem Schauspielstich | / | |

| 3 | Plungermenge | 3 | 3 | Stück | |

| 4 | Kolbendurchmesser | 50 | 50 | mm | |

| 5 | Arbeitsplan | 100 | 100 | mm | |

| 6 | Drehgeschwindigkeit Eingang | 390~ 900 | 590~ 1330 | r/min | |

| 7 | Ausgabe | 32~ 75 | 50~ 110 | L/min | |

| 8 | Arbeitsdruck | 36 | 40 | MPa | |

| 9 | Saugrohrdurchmesser | 64 | 64 | mm | |

| 10 | Entladungsrohrdurchmesser | 25 | 25 | mm | |

| 11 | Maße | 2820× 1270 × 1220 | 2820× 1270 × 1220 | mm | |

| 12 | Gesamtgewicht | 3380 | 3450 | Kg | |

Beschreibung von Hochdruckpumpen

Diese Serie von Hochdruckfürstpumpen ist eine leichte Hochdruckpumpe, die sorgfältig entwickelt wurde, um die wachsende Hochdruckfürrehetechnologie zu erfüllen. Die neueste Generation von Produkten, die Medium wie klares Wasser und Zementschlamm mit hoher Dichte pumpen können, und mit einem Geschwindigkeitskontrollmechanismus ausgestattet, kann als variable Pumpe verwendet werden. Es hat die Eigenschaften vernünftiger Parameter, Fortgeschrittene Technologie, Zuverlässige Qualität, Ausgezeichnete Leistung und schönes Aussehen.

Arbeitsmedium der Verhuschungspumpen

Das Arbeitsmedium muss durch einen Filter von gefiltert werden 20 Netz oder mehr, um schädliche feste Partikel herauszufiltern. Wenn es im Medium mehr feste Partikel gibt, Erhöhen Sie die Anzahl der Filtrationen. Die durch schlechten Filtration verursachten gemeinsamen Fehler sind wie folgt:

- Da das hydraulische Ende der Schlammpumpe als Gummi versiegelt ist, Die festen Partikel werden durch die Ventilplatte unter hohem Druck in den Gummi gedrückt. Wenn die Partikel groß sind, Die Ventilplatte wird gepolstert, Die Dichtung scheitert und beschädigt die Ventilplatte und den Ventilsitz.

- Wenn die Partikel klein sind, Aber die Menge ist groß, Nach dem Ansammlung bis zu einem gewissen Grad, Die Ventilplatte wird gepolstert, die Dichtung scheitert und beschädigt den Ventilsitz und die Ventilplatte.

- Weil die Lücke zwischen der Ventilplatte und der Grenzhülle klein ist, Wenn die größeren Partikel eingedrungen sind, Die Ventilplatte kann stecken bleiben, Dadurch funktioniert die Pumpe abnormal und beschädigt den Ventilsitz.

- Benutzer von Zementschlamm sollten beachten: Aufgrund der verschiedenen verwendeten Zementhersteller, Die Größe und Menge der Eisenbohnen im Zement sind unterschiedlich. Bitte verwenden Sie einen geeigneten Filter gemäß der Situation, um sicherzustellen, dass die Hochdruckpumpe normal funktionieren kann.

Hauptfunktion der Hochdruckpumpe

Hochdruckpumpe wird hauptsächlich für die weiche Bodenbehandlung verwendet, Hochdruck-Jet-Fugen; Hochdruck-Wasserstrahl hilft das Bruch der Felsbrüche; hydraulische Requisiten für Kohlemine für unterirdische Hydraulik; verankerte Hydraulikausdehnungsmetallpumpe für Hochdruckwasser; unterirdische großflächige Pipeline-Baggerreinigung; Chemische Pumpe; Hochdruckwasserstrahlhorizontal durch Lochbohrungen; Andere Verwendungspumpen verwenden Verhuschungspumpe;