وصف المشروع

PLD 2400 آلة خلط الخرسانة

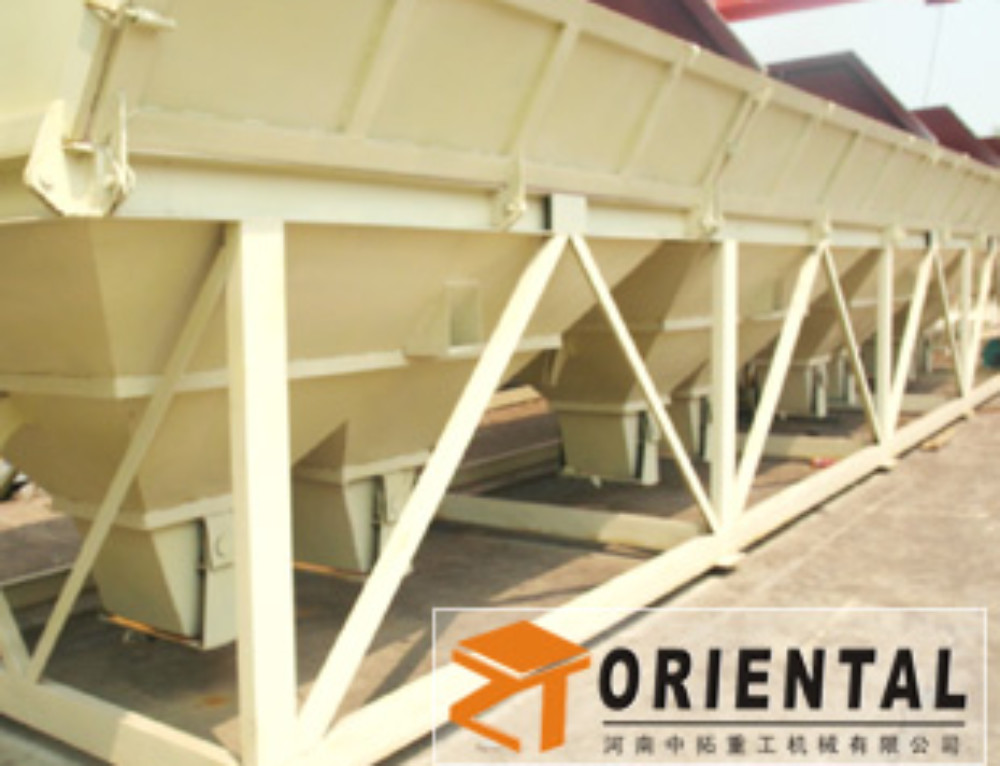

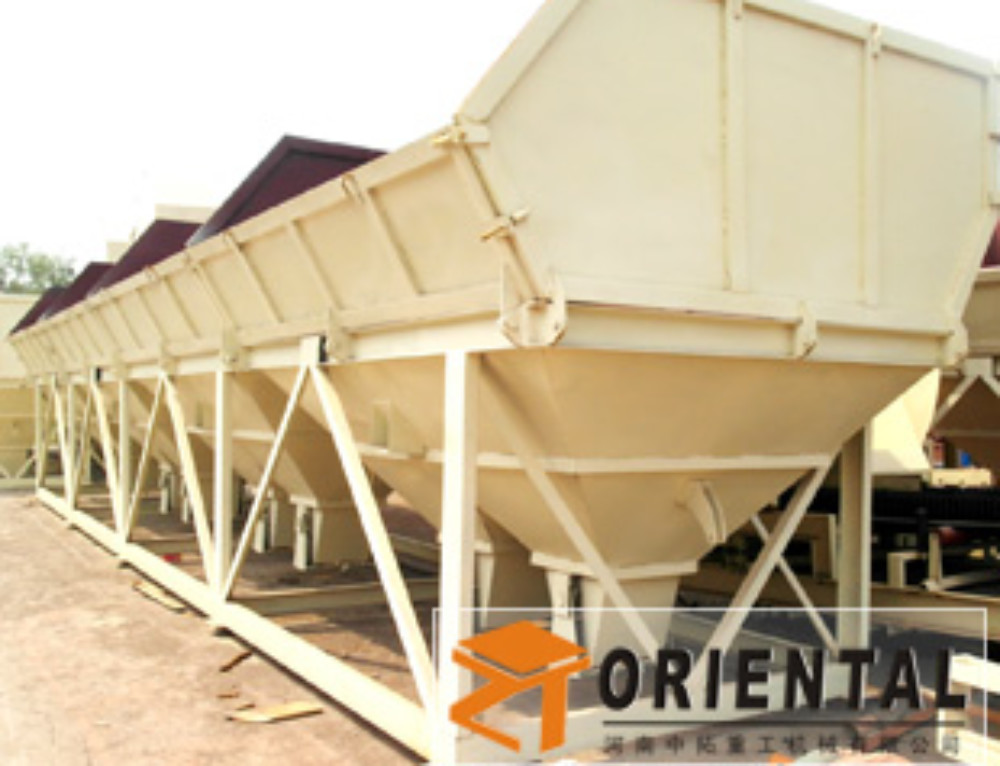

PLD series concrete batching machine is a kind of equipment with automatically batching material on the front desk and using mixer together. It can automatically finishing the batching procedures of 2-5 kinds of materials (second grade concrete) such as sand, stone, cement according to users’ requirement.

![]()

| model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Weighing bucket

capacity |

800ل | 1200ل | 1600ل | 2400ل | 3200ل | 4800ل |

| Hopper capacity | 2*1.2m3 | 3*2.5m3 | 3*3m3 | 3*12m3 | 3*20m3 | 4*25m3 |

| Production rate | 48م3/ساعة

(dry material) |

56م3/ساعة

(dry material) |

75م3/ساعة

(dry material) |

120م3/ساعة

(dry material) |

160م3/ساعة | 280م3/ساعة |

| Batching accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Maximum weighing

value |

2000كلغ | 3000كلغ | 3000كلغ | 4000كلغ | 5000كلغ | 8000كلغ |

| Ingredients species | 2-3 | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 |

| Feeding height | 2400مم | 2900مم | 2900مم | 4250مم | 4500مم | 2300مم |

| Feeder belt speed | 1m/s | 1m/s | 1m/s | 1.6m/s | 1.6m/s | 1.25m/s |

| power | 3×3=9kw | 4×3=12kw | 3×4=12kw | 7.5kw | 11kw | 18.5kw |

| Total weight | 2450كلغ | 4500كلغ | 5600كلغ | 8500كلغ | 10200كلغ | 14000كلغ |

| Dimensions (الطول × العرض × الارتفاع) |

1580*

2780* |

9400*

2020* |

9400*

2270* |

13200*

3250* |

13100*

3340* |

15520*

3900* |

PLD series concrete batching machine is a kind of equipment with automatically batching material on the front desk and using mixer together. It can automatically finishing the batching procedures of 2-5 kinds of materials (second grade concrete) such as sand, stone, cement according to users’ requirement. These serial products adopt electronic weighing, computer control, digital display, wired remote control operation, and have such advantages as accurate weighing, high precision batching, quick speed, strong control function and convenient operation. After this serial concrete batching machine with relative concrete mixer, different types and specification combined concrete mixing station can be formed.

1.The concrete batching machine, with 2-5 aggregate hoppers, can be assembled as per individual requirements. There are independent weighing hoppers and belt conveyor under the aggregate hoppers that could be designed as steel structure type, underground and half-underground types. The aggregates can be fed into the aggregate hoppers by loader or belt conveyor.

2.Discharging system adopts pneumatic fan-shaped door,making block and leak absent,discharging quick,energy saved and environment protected ,storing hopper can realize quick or slow batching

3.Each and every aggregate is weighed individually or accumulatively, and the weighing accuracy is guaranteed. The accuracy of aggregates proportional ratio is realized through computer control system, which automatically re-feeds the aggregates if there is shortage of weight, warns if there is overweight.

Temperature sensor:

Supply the exact temperature of aggregate,applicable to some area such as high temperature,freezing and area with special requirement for temperature

Microwave hygronom:

Supply the exact water ratio of aggregate,during batching ,the corresponding water ratio is reduced and the batching precision is improved

Preheat pipe:

The outlet of the pipe is ready in advance,heating the aggregate through preheating gas,applicable to freezing area

Rainproof shed:

Avoid to drench aggregate ,applicable to rainfall area ,filtration shaker,supply you with eligible aggregate materials to improve the quality materials

We can design and make the batching system of aggregate according to the user’s circumstance,field and special requirement