وصف المشروع

Cement Silos Accessories

Cement silo with Level Indicator / Safety Valves / Dust collector / Pneumatic Butterfly Valve / Arch breaker device

Cement silo Accessories with Cement silo with Level Indicator / Safety Valves / Dust collector / Pneumatic Butterfly Valve / Arch breaker device

![]()

Cement Silo Maximum-Minimum Level Indicator

Maximum-Minimum Level Indicator

Cement Silo level indicator is a limit value indicator that is used to check the cement filling volume in the cement silo.

This indicator is used to determine the max and min level of the cement in the cement silo by using of rotary motion.

When the cement amount in the cement silo reaches the turning pedal of the indicator, there occures a signal shows that the cement amount has reached to that level. When the cement amount goes down under the indicator level, the turning pedal starts to move again and thus the other units of the system start to move too. Cement level indicators usually are used to determine filling level of the material which has 0,5-2,0 ton/m³ density in the cement silo and mostly they are assembled on bottom and top parts of the cement silo.

High Pressure cement Safety Valves

High Pressure cement silo Safety Valves

High pressure cement safety valves are used the discharge the high pressure in the cement silo. Those valves start to run when the pressure value reaches the pre-set pressure limit value.

Those valves are the equipments that keeps the pressure in the cement silo in desired values and prevent the cement silo filter from breaking down.

The cement is transferred from silobus to cement silo with high pressure. In case there is no cement in the silobus, only the air is transferred into the cement silo and thus there occures high pressure in the cement silo. At this moment if high pressure safety valves do not start to run , the cement silo and the cement silo filter can be damaged seriously.

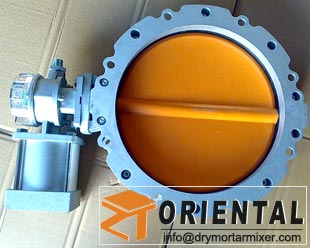

Cement Silo Pneumatic Butterfly Valve

Pneumatic Butterfly Valve

Pneumatic Butterfly Valve using pneumatic actuator driven by mechanical disc, rotate 70o open and close. Disc working position through the line and switch the signal display, the throttle valve opening and closing speed can be adjusted. The valve can be remote control unit can also be remote centralized control, can also be input into a computer for process control. The valve in the non-normal circumstances, the wrench can be used for manual operation.

Cement silo dust collector Filter cartridge And Technical Parameters

Cement silo dust collector

Cement silo dust collector, deduster,Dust Collector (24 square) dust catcher is used in every kinds of silo and storage tank.Its collect area is 24 square. Adapted Impulse and have 14 filter elements insides. Cement silo dust collector makes large dust collector area and good effects.

Technical parameters:

| Dust removal area | 20m²/24m² |

| Dust removal amount | >1500m³/h |

| Filter number | 12/14 |

| Filtration efficiency | 99.9% |

| Fan motor power | 150W(380V) |

| Clean way | Intermittent pulsed/intermittent vibration type |

| Simplified materials | High strength carbon steel |

| Simplified color | beige |

| وزن | 120 كلغ / 130 كلغ |

Cement Silo Arch breaker device

Help flow air nozzle is a easy to install, use a wide range of flow equipment to help break the arch can be installed in the hopper, silo, especially pipe. The front of the gas nozzle is porous metal, the external access to high-pressure air through the mouth after the gas dispersed in the air around the mouth, to promote powder flow, to help the flow effect. Flow volume to determine the effect of the gas nozzle, different conditions require different powder and the container volume of the gas nozzle. This product has installation and maintenance convenience, low prices, traffic and other advantages of the obvious effect.

Help flow air nozzle is a easy to install, use a wide range of flow equipment to help break the arch can be installed in the hopper, silo, especially pipe. The front of the gas nozzle is porous metal, the external access to high-pressure air through the mouth after the gas dispersed in the air around the mouth, to promote powder flow, to help the flow effect. Flow volume to determine the effect of the gas nozzle, different conditions require different powder and the container volume of the gas nozzle. This product has installation and maintenance convenience, low prices, traffic and other advantages of the obvious effect.